You’re searching for the Mollar CGT20750 drawing PDF, and you’re probably wondering where to find it and what makes this document so valuable. Here’s what you need to know: the Mollar CGT20750 drawing PDF is a technical document that contains detailed schematics, component breakdowns, and maintenance instructions for the CGT20750 tool. This guide will show you exactly how to access, understand, and use this PDF to get the most from your equipment.

What Makes the Mollar CGT20750 Drawing PDF Essential

The Mollar CGT20750 drawing PDF serves as a technical resource providing detailed schematics, assembly guides, and maintenance instructions. Think of it as your tool’s complete manual wrapped into one downloadable file.

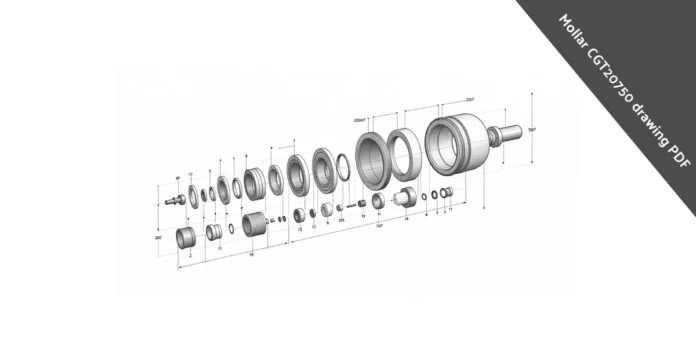

This PDF typically includes exploded views showing every component, part numbers for ordering replacements, and assembly diagrams that remove guesswork from repairs. The document contains component labels with unique part numbers, lines, and arrows indicating assembly order, and technical symbols denoting material types and torque specifications.

For professionals, DIY enthusiasts, and beginners, this document bridges the gap between confusion and confidence. You’ll spend less time troubleshooting and more time working when you have the right information at your fingertips.

How to Download the Mollar CGT20750 PDF

Getting your hands on the official PDF shouldn’t involve hours of searching. Access the Mollar CGT20750 drawing PDF through the official Mollar website, authorized distributors, or by contacting customer support.

Start by visiting Mollar’s official website. Navigate to their support or resources section, then search for the CGT20750 model. Many manufacturers now provide downloadable manuals in PDF format on their websites.

Authorized distributors represent another reliable source. Authorized distributors are trusted partners of Mollar, providing genuine and reliable access to the CGT20750 drawing PDF. You can find these distributors listed on Mollar’s official site under “Where to Buy” or “Partners” sections.

Here’s a quick checklist for downloading:

- Verify you’re on an official site (check the URL carefully)

- Look for the support or technical documents section

- Select your specific model number (CGT20750)

- Download the PDF and save it to multiple locations

- Consider printing a physical copy for workshop reference

Avoid third-party sites that aren’t authorized. These sources may offer outdated versions or incorrect specifications that could lead to faulty repairs.

Understanding Your Mollar CGT20750 Components

The drawing PDF is organized logically to guide users through the device’s internal and external components. Let’s break down what you’ll find inside.

The motor assembly and power supply section details the brushless motor, battery housing, and connectors. This shows you how power flows through your tool and where potential electrical issues might originate.

Your handle assembly gets its own section. The handle’s design is highlighted, including switches, grips, and safety locks. Understanding this area isn’t just about repairs—it’s about operating your tool safely and comfortably.

The cutting mechanism section illustrates blade assembly, guards, and mounting brackets. This becomes critical when you need to replace worn blades or adjust cutting components.

Electrical wiring diagrams show connections between the battery, motor, and controls. When your tool won’t start, these diagrams become your troubleshooting roadmap.

Key Features of the Mollar CGT20750 Tool

Before diving deeper into the PDF, you should understand what makes the CGT20750 worth mastering. Key features include a calibrated mechanism for enhanced precision, customizable line thickness with a unique tension adjustment feature, and a fine point for detailed work.

The tool’s ergonomic design stands out. The CGT20750 emphasizes ergonomic design, providing a comfortable grip that minimizes strain and promotes prolonged use. You can work longer without experiencing hand fatigue or reduced accuracy.

Constructed with high-quality materials, the Mollar CGT 20750 is built to withstand the rigors of regular use. This durability means your investment lasts longer and performs consistently across hundreds of projects.

The adjustable features let you customize line thickness instantly. Whether you need intricate details or bold strokes, the tension adjustment mechanism gives you control without switching tools.

Using the PDF for Maintenance and Repairs

Your PDF transforms from a reference document to a repair guide when something goes wrong. The drawing PDF guides users on how to identify worn or broken parts that need replacement, understand lubrication points to reduce friction and wear, and follow cleaning instructions to avoid damage from debris buildup.

Start with routine inspections. The PDF shows you exactly where to look for wear patterns, which components need regular cleaning, and how often lubrication should occur. Regular inspection using the drawing ensures parts are correctly assembled and functioning, which extends the tool’s life and prevents breakdowns.

When troubleshooting issues, the PDF becomes invaluable. Can’t get your tool to start? Users can refer to the wiring diagrams to check battery connections, inspect the motor assembly section for signs of wear or damage, and cross-check part numbers to order exact replacements.

The PDF also includes maintenance schedules. You’ll find recommendations for tightening screws after specific usage periods, replacing certain components at regular intervals, and proper storage techniques that prevent moisture and dust damage.

Common Parts You’ll Reference

Certain components need attention more frequently than others. Understanding these parts helps you navigate your PDF efficiently.

The brushless motor powers your cutting blade. Check for overheating regularly, as this indicates potential problems before they become serious failures.

Battery connectors link your power source to the motor. Clean terminals regularly to maintain proper electrical contact and prevent power issues.

Your cutting blade performs the trimming task. Inspect for damage before use to avoid safety hazards and poor cutting performance.

The handle assembly houses controls and safety features. Ensure switches operate smoothly to maintain full control during operation.

Each component has specific part numbers in your PDF. Keep these handy when ordering replacements to guarantee you receive exact matches for your model.

Safety Guidelines from the PDF

Safety information scattered throughout your PDF deserves special attention. Always disconnect the power supply before performing maintenance or repairs. Avoid using the tool in wet conditions or near water. Wear insulated gloves and safety goggles to protect against electrical shocks.

The PDF includes safety symbols and warnings that you can’t ignore. These reminders protect you during repairs and regular operation. Understanding and applying these safety protocols prevents accidents during repair or operation.

Before any maintenance work, disconnect power completely. This single step prevents the majority of electrical accidents during repairs.

Never touch electrical components with your bare hands, even when the power is disconnected. Static electricity or residual charge can still present risks.

Follow torque specifications when reassembling components. Over-tightening or under-tightening bolts can lead to mechanical failures that compromise safety and performance.

Navigating the PDF Structure

The document typically includes bookmarks for quick access to different sections, such as components, schematics, and technical specifications. Learning to navigate efficiently saves time when you need answers quickly.

Use the search function to locate specific parts or instructions instantly. Instead of flipping through dozens of pages, type in the component name or part number.

Zoom in on detailed diagrams when precision matters. Zooming in on detailed diagrams ensures clarity, while full-screen mode enhances readability.

The table of contents provides your roadmap. The table of contents provides a clear overview, allowing users to jump to relevant sections effortlessly.

Consider organizing your PDF with digital notes or highlights. Most PDF readers let you add annotations, which helps you mark frequently referenced sections or add personal observations about your specific tool.

Extending Your Tool’s Lifespan

The drawing PDF also includes recommendations for enhancing the tool’s lifespan. These practices keep your CGT20750 performing at its best for years.

Store your tool properly between uses. Keep it in a dry environment away from extreme temperatures. Moisture and dust are the enemies of mechanical and electrical components.

Tighten screws and bolts regularly. Regular tightening of screws and bolts prevents loosening from vibrations that occur during normal operation.

Replace worn parts promptly. Don’t wait until complete failure. Timely replacement of parts listed in the PDF’s spare parts section prevents damage to other components.

Clean your tool after each use. A simple wipe-down removes debris that can accumulate and interfere with moving parts. This five-minute habit prevents hours of deep cleaning later.

Applications Across Different Fields

The Mollar CGT20750 serves diverse users, and your PDF helps you maximize its potential in your specific field.

Artists appreciate the Mollar CGT 20750 for its ability to create detailed and expressive drawings. The precision tip handles fine details that other tools miss.

In architecture and design, the CGT 20750 is used to create detailed floor plans, elevations, and conceptual sketches. Accuracy ensures designs are both visually appealing and technically correct.

Engineers use the CGT 20750 for drafting technical schematics and blueprints. Precision and clarity prove crucial for accurately conveying complex systems and components.

Hobbyists and DIY enthusiasts also benefit from comprehensive documentation. The PDF makes professional-grade capabilities accessible to anyone willing to learn.

Final Thoughts

The Mollar CGT20750 drawing PDF represents more than technical documentation—it’s your complete resource for understanding, maintaining, and repairing your tool. By accessing the official PDF through authorized channels, you ensure you’re working with accurate, up-to-date information.

Keep your PDF accessible during every project. Whether stored digitally on your phone or printed in your workshop, quick reference saves time and prevents costly mistakes. Regular consultation of the maintenance sections extends your tool’s life and keeps performance consistent.

Remember that authorized sources provide the most reliable documentation. While third-party sites might seem convenient, they can’t guarantee accuracy. Invest a few extra minutes in finding official resources—your tool’s performance depends on it.

FAQs

Where can I download the official Mollar CGT20750 PDF?

Visit the official Mollar website and navigate to their support section. You can also contact authorized distributors or customer support for direct access to the PDF.

What information does the drawing PDF contain?

The PDF includes detailed schematics, exploded views of components, part numbers, assembly instructions, maintenance schedules, and safety guidelines specific to the CGT20750.

Can I use third-party PDFs for my Mollar CGT20750?

It’s not recommended. Third-party sources may contain outdated information or incorrect specifications that could lead to improper repairs or safety issues.

How often should I reference the maintenance section?

Consult the maintenance section before each major use and follow the recommended service intervals outlined in the PDF. Regular checks prevent unexpected breakdowns.

What should I do if I can’t find a specific part in the PDF?

Contact Mollar customer support directly with your model number and the part you’re looking for. They can provide additional documentation or direct you to the correct section of your PDF.