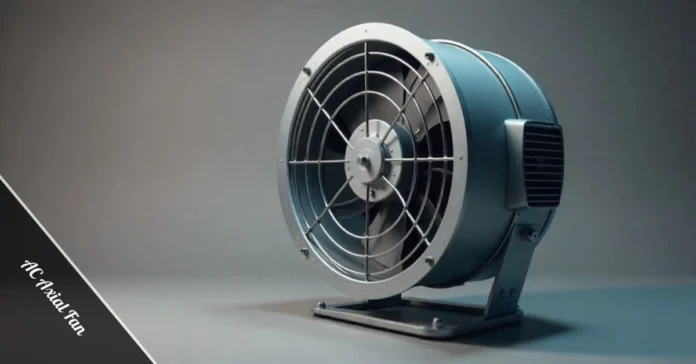

An AC axial fan is a cooling device that moves air parallel to its rotating shaft using alternating current power (115V or 230V). These fans feature a simple design with an AC motor, rotating blades, and a housing that delivers high airflow at low pressure. They’re ideal for cooling large spaces, industrial equipment, and HVAC systems where continuous operation is required.

AC axial fans excel in applications requiring substantial air movement with minimal pressure resistance. They connect directly to standard electrical outlets without converters, making them practical for industrial machinery, ventilation systems, and electronics cooling. Most models operate continuously for years with minimal maintenance, offering reliable performance at a lower upfront cost than DC alternatives.

What Is an AC Axial Fan

An AC axial fan uses alternating current to drive air parallel to the fan’s axis of rotation. The term “axial” describes how air flows through the fan in a straight line, entering and exiting along the same axis as the motor shaft.

These fans consist of three main components: an AC motor, rotating blades (impeller), and a housing. When powered by AC electricity, the motor spins the blades, creating airflow that moves in a linear path. Most models operate on either 115 VAC (North America) or 230 VAC (Europe and Asia).

Unlike centrifugal fans that discharge air at 90-degree angles, axial fans maintain straight-line airflow. This makes them highly efficient for applications requiring large air volumes with minimal pressure resistance, such as ventilation systems, electronics cooling, and equipment temperature control.

How AC Axial Fans Work

AC axial fans operate through a straightforward mechanical process. The AC motor receives alternating current from the power supply, causing the rotor to spin. This rotation drives the fan blades, which are angled to catch and propel air forward.

The blades act like propellers. As they rotate, they create a low-pressure zone behind them and a high-pressure zone in front. Air naturally moves from high to low pressure, creating continuous airflow through the fan housing.

Most AC axial fans use shaded-pole motors or external rotor motors. Shaded-pole motors are simpler and less expensive but run at fixed speeds. External rotor motors integrate directly into the fan impeller, creating a more compact design with better efficiency.

The housing design affects performance significantly. Short nozzle housings provide basic protection and mounting options. Long nozzle housings focus airflow more effectively, increasing static pressure capability by up to 30%.

Types of AC Axial Fans

Standard Muffin Fans: These compact, square-framed fans range from 25mm to 254mm. They’re the most common type, found in electronics cooling, server racks, and industrial control panels.

High-Temperature AC Fans: Designed for extreme environments, these fans operate reliably at temperatures up to 70°C. They use heat-resistant materials and specialized bearings for furnaces, ovens, and industrial machinery.

Waterproof and IP-Rated Fans: These units feature sealed housings with IP54, IP55, or IP67 ratings. The ingress protection prevents dust and moisture damage for outdoor installations and food processing facilities.

Tubeaxial Fans: These fans mount inside cylindrical ducts or tubes. The enclosed design focuses airflow and increases pressure capability for ductwork and exhaust systems.

Vaneaxial Fans: Adding guide vanes before or after the impeller straightens airflow and reduces turbulence. This design improves efficiency by 10-15% compared to standard axial fans.

Key Specifications to Consider

Airflow (CFM): Measured in cubic feet per minute, airflow indicates how much air the fan moves. Small 80mm fans typically deliver 20-50 CFM, while large 254mm models can reach 400+ CFM.

Static Pressure: Expressed in Pascals (Pa), static pressure measures the fan’s ability to move air against resistance. AC axial fans typically handle 50-270 Pa.

Voltage and Frequency: Most AC fans operate on 115 VAC or 230 VAC at 50/60 Hz. Always match the fan voltage to your electrical supply.

Power Consumption: AC axial fans typically consume 15-200 watts, depending on size. Compare watts per CFM to evaluate efficiency.

Noise Level: Most AC axial fans produce 30-60 dBA. Larger, slower-rotating fans generally run quieter than small, high-speed models.

Bearing Type: Ball bearings last 40,000-60,000 hours at 60°C and handle higher temperatures. Sleeve bearings cost less but only last 20,000 hours at 45°C.

AC Axial Fan vs DC Axial Fan

Power Requirements: AC fans connect directly to wall outlets (115V or 230V) without adapters. DC fans require low-voltage power (5V, 12V, 24V) from batteries or power supplies.

Energy Efficiency: DC fans consume 50-70% less power than comparable AC fans. For battery-powered or energy-conscious applications, DC technology saves significant electricity.

Speed Control: DC fans offer built-in speed adjustment through pulse width modulation. AC fans need external variable frequency drives for speed control, adding cost and complexity.

Cost: AC fans cost less upfront due to simpler motor technology. A basic AC axial fan runs $15-90, while comparable DC models range from $30-150.

Application Suitability: Choose AC fans for industrial machinery, HVAC systems, and applications with available AC power. Select DC fans for electronics cooling, automotive applications, and energy-sensitive installations.

Common Applications

HVAC Systems: These fans circulate air through heating, cooling, and ventilation systems. Sizes from 172mm to 280mm provide the high airflow volumes HVAC systems require.

Industrial Equipment Cooling: Generators, air compressors, welding machines, and CNC equipment all use AC axial fans to prevent overheating and maintain operational stability.

Electronics and Server Racks: Data centers and network equipment rooms use AC fans to cool servers, switches, and storage arrays continuously.

Refrigeration Systems: Walk-in coolers, freezers, and commercial refrigeration units employ AC axial fans in condenser cooling to dissipate heat from refrigerant.

Agricultural Ventilation: Barns, greenhouses, and livestock facilities use large AC fans (200mm+) for air circulation to control humidity and maintain animal health.

Cabinet and Enclosure Cooling: Electrical cabinets, control panels, and equipment enclosures need ventilation to prevent component failure. Small AC fans (80mm-120mm) fit easily into cabinet designs.

Installation and Mounting

Mounting Orientation: Most ball bearing fans mount in any position. Sleeve bearing fans require horizontal mounting to maintain proper lubrication.

Airflow Direction: Fans have designated inlet and outlet sides. The motor hub side typically represents the exhaust. Verify airflow arrows on the housing.

Clearance Requirements: Leave at least 25mm of unobstructed space on both inlet and outlet sides. Obstructions reduce airflow by 20-40% and increase noise.

Vibration Isolation: Mount fans on rubber grommets or vibration-damping washers to reduce noise transmission, especially for fans exceeding 120mm.

Environmental Protection: For outdoor installations, use fans with appropriate IP ratings. Add protective hoods to prevent rain intrusion.

Maintenance and Troubleshooting

Cleaning Schedule: Inspect fans every three months in clean environments, monthly in dusty conditions. Accumulated dirt on blades reduces airflow efficiency by 10-30%.

Bearing Maintenance: Ball bearing fans require minimal maintenance. Sleeve bearing units may need lubrication every 12-18 months if designed for it.

Common Problems:

Fan won’t start: Check power supply voltage and verify connections are secure. A seized bearing may prevent startup.

Reduced airflow: Clean blades and housing. Check for obstructions in the airflow path.

Excessive noise: Inspect for loose mounting hardware or damaged blades. Replace worn bearings if grinding occurs.

Motor overheating: Ensure adequate ventilation around the motor and verify voltage matches specifications.

When to Replace: Replace fans when bearing noise becomes excessive, airflow drops below 70% of rated performance, or the motor overheats repeatedly.

Selecting the Right AC Axial Fan

Calculate Required Airflow: Determine your cooling load in BTU/hour or watts. Use this formula: CFM = (BTU/hour) ÷ (1.08 × ΔT). Add 20% margin for efficiency losses.

Assess Static Pressure: Identify all airflow restrictions (filters, ducts, heat exchangers) and sum their pressure resistance. Select a fan rated for this pressure while delivering the required CFM.

Consider Size Constraints: Measure available mounting space. Larger fans typically run quieter and more efficiently than smaller, high-speed alternatives.

Evaluate Environmental Conditions: Hot environments need fans rated for elevated temperatures. Outdoor installations require weatherproof housings.

Review Power Availability: Match fan voltage to available power. Consider energy consumption over the fan’s lifespan.

Top Manufacturers and Where to Buy

EBM-Papst: German engineering with AC axial fans from 80mm to 800mm. Known for energy-efficient designs and long lifespans.

AC Infinity: US-based manufacturer offering complete fan kits with mounting hardware and speed controllers. Popular for DIY projects and replacement applications.

Sofasco: Specializes in certified AC and DC fans for OEM applications. Size range 25mm to 254mm with custom options.

Delta Electronics: Major supplier of cooling fans for electronics and industrial applications with global distribution.

Where to Purchase: Online distributors like Digi-Key, Mouser Electronics, and Newark carry extensive inventories with same-day shipping. Industrial suppliers like Grainger stock larger fans for commercial applications. Contact manufacturers directly for custom specifications or OEM pricing.

Cost Analysis

Budget Range ($10-$30): Basic 80mm-120mm fans with sleeve bearings. Suitable for non-critical applications. Expect a 2-3 year lifespan.

Mid-Range ($30-$80): Quality 120mm-172mm fans with ball bearings and aluminum housings. Good for most industrial applications. Typical 5-7 year lifespan.

Premium Range ($80-$200): High-performance 172mm-254mm fans with advanced bearings and optimized designs. 7-10+ year lifespan.

Operating Costs: A 120mm AC fan consuming 30 watts running 24/7 costs approximately $26 per year in electricity (at $0.10/kWh).

Final Thoughts

AC axial fans deliver reliable, cost-effective cooling for industrial and commercial applications. Their straightforward design, high airflow capacity, and compatibility with standard AC power make them practical choices for heavy-duty cooling tasks.

When selecting an AC axial fan, prioritize matching airflow and pressure requirements to your specific cooling needs. Quality fans from reputable manufacturers may cost more initially but deliver better performance and longer service life. Proper installation and routine maintenance ensure your AC axial fans operate efficiently throughout their rated lifespan.