Electrical fault finding identifies and resolves issues in electrical systems through systematic testing, diagnosis, and repair. Common faults include short circuits, overloads, and earth faults. Professional electricians use multimeters, insulation testers, and thermal cameras to detect problems, ensuring safety and preventing equipment damage or fire hazards.

Your lights flicker without warning. A circuit breaker trips repeatedly. The equipment stops working with no clear explanation.

These problems signal electrical faults that demand immediate attention. Left unchecked, they create fire risks, damage expensive equipment, and threaten personal safety.

This guide shows you how to identify, diagnose, and fix electrical problems safely. You’ll learn proven techniques that professionals use daily, understand when to call an expert, and discover how to prevent faults before they occur.

What Makes Electrical Fault Finding Critical

Electrical systems power homes and businesses around the clock. When faults develop, the consequences extend beyond mere inconvenience.

Research from the National Fire Protection Association shows that electrical failures caused 13% of home fires between 2015-2019, resulting in property damage exceeding $1.3 billion annually. Many of these incidents stemmed from undetected faults that could have been identified through proper testing.

Professional fault-finding saves money by catching problems early. A 2023 study by the Electrical Safety Foundation International found that businesses using systematic fault detection reduced equipment downtime by 34% and cut emergency repair costs by 42%.

Safety drives the need for rapid fault detection. Electrical issues create shock hazards, arc flash risks, and fire dangers. Technicians who follow structured fault-finding methods resolve problems faster while maintaining safe working conditions.

Common Types of Electrical Faults You’ll Encounter

Electrical systems fail in predictable patterns. Recognizing these fault types helps you diagnose problems quickly.

Short circuits occur when current flows through an unintended path, typically where damaged insulation allows conductors to touch. The resulting surge trips protective devices and can generate dangerous heat. Signs include burning smells, scorched outlets, and breakers that trip immediately when reset.

Overloads happen when circuits carry more current than designed for. Multiple high-power devices on a single circuit force excessive current through wiring sized for smaller loads. Circuit breakers trip repeatedly under these conditions, and wiring feels warm to the touch.

Earth faults send current flowing to ground through damaged equipment or wet conditions. Ground Fault Circuit Interrupters (GFCIs) detect these faults and cut power within milliseconds. Persistent GFCI trips signal moisture intrusion, damaged cables, or deteriorating appliance insulation.

Open circuits create breaks in the current path. Loose connections, broken wires, or failed components prevent electricity from reaching its destination. Devices won’t power on, lights stay dark, and voltage tests show power at one point but not downstream.

According to a 2024 report from the Institute of Electrical and Electronics Engineers, short circuits account for 31% of residential electrical faults, overloads cause 28%, earth faults comprise 24%, and open circuits make up 17%.

Six-Step Method for Electrical Fault Finding

Professionals follow a systematic approach that reduces diagnostic time and prevents overlooked issues.

Step 1: Gather Evidence

Start by collecting all relevant information about the problem. Ask when the fault first appeared, whether it’s intermittent or constant, and what conditions trigger it. Check if recent work or weather events preceded the issue.

Walk the site and use your senses. Look for visual damage like burn marks, discoloration, or physical damage. Listen for buzzing or humming sounds. Smell for burning or ozone odors. Feel for excessive heat, but never touch live circuits.

Document your findings with photos and notes. This evidence becomes invaluable if the fault proves complex or requires multiple visits.

Step 2: Analyze the Evidence

Review your collected information and eliminate irrelevant details. Focus on facts that point toward specific fault types.

A circuit that trips only when running a particular appliance suggests an overload or fault within that device. Intermittent problems during rain point to moisture intrusion. Faults occurring across multiple circuits indicate issues at the distribution panel.

Compare symptoms against known fault patterns. This analysis narrows your investigation to the most likely causes.

Step 3: Locate the Fault

Use systematic testing to pinpoint the exact fault location. Start at the power source and work downstream, testing each segment.

For open circuits, measure voltage at progressive points along the path. The location where the voltage disappears marks the fault. For short circuits, check the resistance between conductors. Zero or very low resistance indicates where the short exists.

Thermal imaging cameras identify hot spots indicating loose connections or overloaded components. These tools detect problems before they fail catastrophically.

Step 4: Determine Root Cause

Finding the fault location isn’t enough. You must identify why it occurred to prevent recurrence.

A burned wire might result from loose terminals, undersized conductors, or excessive load. Examine the installation quality, check if the wire gauge matches the load, and review what equipment runs on the circuit.

Moisture damage requires finding the water source. Mechanical damage needs to identify what caused the impact. Understanding root causes ensures your repair addresses the actual problem.

Step 5: Repair the Fault

Execute repairs following electrical codes and manufacturer specifications. Replace damaged components with properly rated parts. Secure all connections tightly and confirm correct wire sizing for the load.

Never take shortcuts. Using incorrect wire gauges, bypassing safety devices, or making temporary repairs creates new hazards. Professional-grade repairs cost less than dealing with failure consequences.

Step 6: Test the System

Power up the circuit and verify normal operation. Check voltage levels at multiple points to confirm proper distribution. Run connected equipment through full operating cycles.

Monitor the repair for 15-30 minutes during initial operation. Thermal cameras help verify connections remain cool under load. This verification confirms your repair succeeded before you leave the site.

Essential Tools for Electrical Fault Finding

The right equipment transforms complex diagnostics into straightforward procedures.

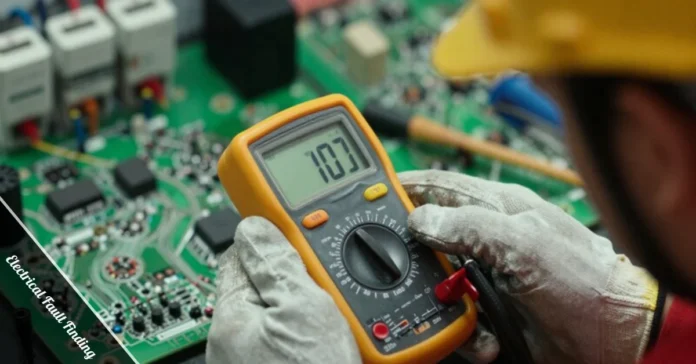

Digital multimeters measure voltage, current, and resistance. Choose models with True RMS capability for accurate readings on modern electronic equipment. Cat III or Cat IV ratings protect you when working on building electrical systems.

Clamp meters measure current without breaking circuits. They’re essential for checking load distribution and identifying overloaded circuits. Models with inrush current measurement help diagnose motor starting problems.

Insulation testers apply high voltage to check wire and component insulation integrity. Degraded insulation creates safety hazards before complete failure occurs. Regular testing catches problems early.

Thermal imaging cameras visualize heat patterns across electrical systems. Hot connections, overloaded circuits, and failing components appear clearly on screen. A 2023 study in the Journal of Electrical Engineering showed thermal imaging reduced diagnostic time by 47% compared to traditional methods.

Circuit tracers identify specific wires in walls, ceilings, or conduit. They save hours when documentation is missing or inaccurate. Wire tracer receivers detect signals through most building materials, letting you map circuits quickly.

Oscilloscopes display electrical waveforms over time. They’re crucial for diagnosing intermittent faults, power quality issues, and problems in electronic control systems. Modern portable oscilloscopes cost less while offering more features than ever before.

Safety Requirements During Fault Finding

Electrical work creates serious injury risks. Following safety protocols protects you and others on site.

Always verify circuits are de-energized before touching conductors. Test with a voltage detector even if you switched the breakers off. Induced voltage from adjacent circuits or backfeeding can energize supposedly dead wires.

Wear appropriate personal protective equipment. Insulated gloves rated for the working voltage, safety glasses, and arc-rated clothing protect against electrical hazards. Steel-toed boots with an electrical hazard rating provide additional protection.

Use insulated tools designed for electrical work. These tools prevent accidental contact with live parts and resist current flow if you touch energized components.

Follow lockout/tagout procedures when working on equipment that others might energize. Physical locks and warning tags prevent someone from restoring power while you’re working.

The Occupational Safety and Health Administration reports that proper safety procedures reduce electrical injuries by 73%. Don’t skip safety steps to save time.

When to Call a Professional Electrician

Some electrical problems require expert knowledge and specialized equipment.

Call a licensed electrician immediately for:

- Repeated circuit breaker trips with no obvious cause

- Burning smells from outlets, switches, or panels

- Sparks or arcing when using electrical devices

- Shocks from appliances, switches, or outlets

- Buzzing sounds from electrical panels or outlets

- Lights that dim when appliances start

- Any work on the main service panels or meter bases

Professional electricians carry comprehensive insurance, understand local electrical codes, and have access to tools most homeowners don’t own. They diagnose complex faults faster and repair them correctly the first time.

Australian electricians must hold proper licenses and maintain continuing education. Check credentials before hiring and verify they carry current insurance coverage.

Technology Advances in Fault Finding

Modern diagnostic tools make fault-finding faster and more accurate than ever.

Smart multimeters connect to smartphones via Bluetooth, letting you record measurements automatically. Trend analysis reveals intermittent problems that manual testing might miss. Some models include thermal imaging or clamp meter functions in compact packages.

Power quality analyzers monitor voltage, current, harmonics, and other parameters over extended periods. They identify problems like voltage sags, harmonic distortion, and transients that damage sensitive equipment. The global power quality analyzer market grew 23% in 2024, reflecting increased adoption across industries.

Artificial intelligence now assists with fault diagnosis. Machine learning algorithms analyze symptoms and suggest likely causes based on thousands of previous cases. While not replacing human expertise, AI tools speed initial diagnosis and flag unusual patterns.

Wireless test equipment eliminates measurement cables and allows safer testing from a distance. Technicians can monitor voltage and current while standing away from live panels, reducing arc flash exposure.

Preventing Electrical Faults in Your System

Proactive maintenance prevents most electrical problems before they cause failures.

Schedule professional inspections every three to five years for residential properties, annually for commercial buildings. Inspectors identify deteriorating components, improper installations, and code violations before they create hazards.

Install surge protection at the service entrance and for sensitive equipment. Lightning strikes and utility switching create voltage spikes that damage electronics and shorten equipment life. Whole-house surge protectors cost $200-500 installed but save thousands in equipment replacement.

Avoid overloading circuits. Calculate the total wattage of devices on each circuit and keep it below 80% of the breaker rating. Distribute high-power appliances across multiple circuits.

Monitor your electrical system’s performance. Dimming lights, warm outlets, and frequent breaker trips signal developing problems. Address these symptoms promptly before they escalate into serious faults.

FAQs

How long does electrical fault-finding typically take?

Simple faults like tripped breakers or loose connections resolve in 30-60 minutes. Complex problems involving multiple circuits or intermittent issues may require 2-4 hours for proper diagnosis. Emergency calls receive priority scheduling and typically arrive within 1-2 hours.

Can I perform electrical fault finding myself?

Basic troubleshooting, like checking breaker positions and testing outlets with a voltage detector,s is safe for homeowners. Anything involving opening electrical panels, testing circuits under load, or working with wiring requires licensed electrician expertise and appropriate safety equipment.

What causes most residential electrical faults?

Loose connections account for approximately 35% of residential faults, often developing gradually as terminals corrode or vibration loosens screws. Overloaded circuits cause another 28%, frequently from adding more devices without upgrading wiring. The remaining faults stem from damaged insulation, water intrusion, and component failures.

How much does professional electrical fault-finding cost?

Diagnostic fees typically range from $100 to 250 for the initial assessment, with repair costs varying by fault complexity. Simple fixes like tightening connections or replacing outlets cost $150-300, while rewiring circuits or replacing panels run $500-2,000. Always request written quotes before authorizing work.

What qualifications should I look for in an electrician?

Verify the electrician holds a current electrical contractor license issued by your state regulatory authority. Check for liability insurance and workers’ compensation coverage. Ask about experience with your specific type of electrical system. Online reviews and references provide insight into work quality and customer service.